Zirconium

Critical Minerals and The Energy Transition

Navigating the Zirconium Market

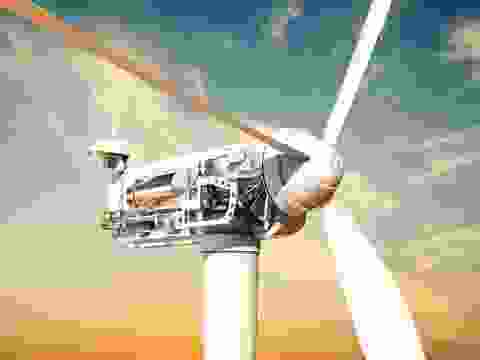

Zirconium, a grey-white transition metal, is celebrated for its exceptional corrosion resistance and high melting point. It is particularly vital in nuclear energy, where it is employed in zircaloy cladding for reactor fuels, taking advantage of its low neutron absorption and stability at elevated temperatures. Beyond nuclear applications, zirconium is also used in the chemical industry as a preferred material for pipes and valves, and in the ceramics industry through derivatives like zircon and zirconia. These compounds significantly enhance the durability and thermal stability of products ranging from domestic kitchenware to sophisticated dental implants. The demand for zirconium is primarily driven by the nuclear sector but also spans advanced ceramics and chemicals. This demand faces challenges such as the environmental impacts of mining and the complexities of managing radioactive waste. Nevertheless, the ongoing need for high-performance materials in industries like aerospace and electronics continues to sustain and expand the use of zirconium. This enduring demand underscores zirconium's essential role in supporting key technological advancements and industrial processes. Zirconium's unique properties, including corrosion resistance, thermal stability, and specialised electrochemical behaviour are fuelling trends in catalysing innovations in extraction, purification, and application technologies. Looking forward, the prospects for zirconium in energy transition applications appear promising. Continuous research and development are dedicated to maximising its potential in cutting-edge energy technologies. From advanced nuclear reactor designs to innovative renewable energy systems and green chemical processes, zirconium is poised to play an increasingly significant role in crafting a sustainable energy future.

An introduction to zirconium

Zirconium demand and end-uses

Zirconium, a versatile transition metal renowned for its unique properties, is gaining prominence as a key material in the global shift towards low-carbon energy systems. Its applications span from traditional nuclear power to cutting-edge renewable technologies and green chemistry processes. As countries around the world accelerate their energy transition initiatives, the demand for zirconium is witnessing substantial growth across multiple sectors, propelled by its exceptional thermal, mechanical, and chemical properties.

Historically, the global zirconium market has encountered cyclical patterns of oversupply and scarcity, influenced by production disruptions, fluctuations in demand, and the emergence of new applications within the energy sector.

In nuclear power, the nuclear-grade zirconium segment is a specialised and expanding market, driven by the increasing role of nuclear energy in global decarbonisation strategies, especially in emerging economies that are boosting their nuclear capacity. Zirconium alloys, known as Zircaloy, are preferred for nuclear fuel rod cladding due to their superior properties. A crucial feature of zirconium is its extremely low neutron absorption cross-section (0.18 barn), which is significantly lower than that of common metals like iron (2.4 barn) and nickel (4.5 barn), ensuring efficient neutron economy in reactor cores critical for sustaining nuclear reactions.

Moreover, zirconium boasts excellent corrosion resistance up to 750°C, high thermal stability, and robust mechanical strength under extreme conditions. Nuclear-grade zirconium requires thorough purification to remove hafnium, which has a neutron absorption cross-section 600 times higher than that of zirconium, rendering it unsuitable for reactor applications.

Zirconium alloys have evolved into a mature product within the nuclear power industry, contributing to enhanced fuel performance through increased fuel burnups and reduced failure rates. Despite the ageing of the current global fleet of nuclear reactors, new facilities are primarily being built in Asia and Eastern Europe, ensuring a stable demand for zirconium alloys.

The nuclear sector accounts for a significant share of high-purity zirconium production, with nuclear reactors potentially incorporating over 100,000 meters of zirconium alloy tubing. Although alternative materials and designs in Small Modular Reactors (SMRs) that do not use zirconium cladding are emerging, the prolonged development timeline for these alternatives indicates that zirconium's demand in nuclear applications is likely to remain strong for decades.

In solar energy technologies, zirconium compounds are increasingly utilised. Zirconium oxide (zirconia) offers a cost-effective and more efficient alternative to traditional semiconductor doping technologies in solar cells. Its application in dye-sensitized cell technology, which can be integrated into architectural elements such as coloured glass windows that double as solar panels, holds the potential to revolutionise building-integrated photovoltaics.

Zircon-containing ceramic roof and façade tiles also enhance energy efficiency by increasing solar reflection, reducing cooling demands, and minimising the carbon footprint of buildings. This passive application plays a vital role in decreasing energy consumption in the built environment, a crucial aspect of decarbonisation strategies.

In the field of advanced energy storage and conversion technologies, which are central to renewable energy integration, zirconium's role is significant:

-

Solid oxide fuel cells: Yttria-stabilized zirconia (YSZ) is highly sought after as an electrolyte material for solid oxide fuel cells, which efficiently convert chemical energy into electrical energy. The premium zircon mined in Indonesia, notable for its low uranium, aluminium, and thorium content, facilitates the production of fused zirconia for these high-tech applications.

-

Battery technologies: Zirconium oxide is an excellent component for enhancing the safety and performance of lithium-ion batteries. It addresses the intermittency challenges of renewable power sources and is especially suitable for home energy systems.

-

Energy storage systems: Zirconium (IV) Chloride is employed to fabricate advanced batteries and supercapacitors, essential for integrating renewable energy sources into power grids by storing excess energy during peak production periods and releasing it during high demand.

Zirconium is increasingly recognised as a pivotal material in hydrogen technologies, essential for profound decarbonisation. It forms stable complexes with hydrogen, showcasing promise for hydrogen storage materials. The zircon derivative ZrMn2 is crucial for the practical, large-scale deployment of hydrogen storage technology. Moreover, zirconia is extensively utilised in electrolysers for hydrogen production, a vital element of the green hydrogen value chain, deemed critical by numerous governments for achieving net-zero emissions.

In the realm of fuel cells, zirconium-based materials enable high-efficiency hydrogen fuel cells for diverse applications, including transportation and stationary power generation. These materials are integral to the development of fuel cell components that support clean energy solutions.

Zirconia catalysts are set to make a substantial impact in the production of sustainable aviation fuel (SAF). These catalysts efficiently transform biomass or waste feedstocks into high-quality SAF that can be utilised in existing aircraft engines without modification, presenting a practical and eco-friendly solution for the aviation industry's decarbonisation efforts.

Research has shown that when combined with silicon nitride, zirconium enhances the catalytic conversion of propane into propylene, a precursor for polypropylene plastic. This process is faster and more energy-efficient than traditional methods, reducing the temperature required for catalytic conversion and subsequently decreasing carbon dioxide emissions, which constitute almost 80% of greenhouse gas emissions in the United States.

Zirconia-based catalysts demonstrate high activity and selectivity in various chemical reactions, facilitating more efficient conversion of raw materials into desired products with reduced waste generation. This efficiency is vital for developing sustainable industrial processes aligned with circular economy principles.

Replacing alumina with zircon in casting and refractory applications significantly cuts energy waste, with studies indicating a 16% lower global warming potential compared to alumina-based alternatives. The automotive and aerospace industries are increasingly adopting zircon to enhance fuel efficiency and reduce environmental impact through applications such as thermal barrier coatings.

Zircon, a primary source of zirconium, also has significant applications in the paint manufacturing sector, also has significant applications in the paint manufacturing sector. Processed into zirconium silicate, this fine, white powder serves as an opacifier, enhancing the opacity and coverage of high-quality interior and exterior paints. Zirconium silicate’s high refractivity improves the paint's hiding power, while its chemical stability prevents reactions with other components, maintaining the paint’s integrity. Additionally, its hardness and abrasion resistance ensure durability, ideal for high-traffic areas. Zirconium silicate is also used in heat-resistant coatings, suitable for high-temperature environments, showcasing its versatility in various industrial and everyday applications.

Zirconium's exceptional durability and corrosion resistance translate into longer product lifecycles, minimising the frequency of replacements and repairs and thus reducing the overall environmental footprint of various industrial applications.

Zirconium supply

Zirconium, a vital element in various high-tech and industrial applications, is predominantly supplied by a handful of countries with significant mineral reserves. The major zirconium-producing countries are Australia, South Africa, China, and Indonesia. These nations are complemented by substantial reserves found in India, Mozambique, and Sri Lanka, making them key players in the global zirconium market.

However, the supply of zirconium faces several challenges that are becoming increasingly acute. Many mining operations report declining grades of zircon in their deposits, which complicates extraction processes and escalates production costs. Moreover, geopolitical risks such as trade restrictions and civil unrest in critical mining regions further disrupt supply chains, affecting the stability and availability of zirconium. These issues have compelled leading producers like Iluka Resources, Kenmare Resources, and PYX Resources to increase prices, particularly for the premium grades that are crucial for high-end applications.

The current landscape of zirconium mineral producers is extensive, indicating a diverse global footprint. In addition to the major producers, countries like Kenya, Ukraine, Madagascar, Nigeria, Senegal, the United States, Brazil, Malaysia, Russia, Vietnam, Sierra Leone, and Sri Lanka also contribute to the global supply. This wide distribution of production capabilities helps to somewhat mitigate the supply risk, although the concentration in certain regions still poses significant challenges.

Historically, many of these nations have been involved in the production of zirconium minerals for decades, establishing a long-standing tradition and expertise in the extraction and processing of this critical material. As the demand for zirconium continues to grow, driven by its applications in areas such as nuclear energy, advanced ceramics, and aerospace technologies, the importance of securing a stable and efficient supply chain becomes even more pronounced. Efforts to enhance mining techniques, expand into new reserves, and improve geopolitical relationships are essential to maintaining the steady flow of zirconium on which so many industries depend.

Current zirconium mineral producers

Historic zirconium mineral producers

Zirconium substitution

Chromite and olivine present alternatives to zircon in specific foundry applications, while dolomite and spinel refractories can substitute for zircon in high-temperature settings.

In nuclear applications, niobium (columbium), stainless steel, and tantalum offer partial substitutes, while titanium and synthetic materials serve in certain chemical processing plants. Control rods in nuclear power plants sometimes opt for boron or cadmium-silver-indium alloys instead of hafnium metal. Additionally, zirconium and hafnium can be used interchangeably in certain superalloys. Refractory materials such as alumina (aluminium oxide) and silicon carbide (SiC) often replace zirconia in high-temperature environments due to their excellent thermal properties.

Titanium's corrosion resistance and strength-to-weight ratio make it a viable substitute for zirconium in select applications, particularly where lightweight materials are advantageous. Magnesium alloys can be potential replacements for zirconium in aerospace components due to their lightweight and mechanical properties.

Cerium compounds, such as cerium oxide, can act as additives in refractories and catalysis applications, offering properties similar to zirconium compounds. Rare earth elements, including lanthanum, neodymium, and yttrium, are used as substitutes or additives in speciality alloys and ceramics employed by zirconium.

Furthermore, carbon composites like carbon fibre reinforced polymers (CFRPs) provide lightweight and high-strength properties, making them suitable alternatives to zirconium in aerospace and automotive applications.

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.