Tungsten

Critical Minerals and The Energy Transition

Navigating the Tungsten Market

The tungsten market, pivotal for its metal with the highest melting point, plays a crucial role across diverse industrial applications due to tungsten's unparalleled strength at high temperatures and density. Dominantly used in creating tungsten carbide for cutting and machining tools, its exceptional hardness and wear resistance are indispensable in sectors ranging from mining and construction to metal machining. Beyond tooling, tungsten's applications span lighting elements, electronic contacts, arc-welding electrodes, and military penetrators, exploiting its unique properties for high-performance requirements. The aerospace industry also relies on tungsten for rocket engine nozzles, demanding materials that endure extreme conditions. However, this market navigates challenges such as concentrated global reserves in China, posing supply vulnerabilities amidst geopolitical tensions, and environmental concerns tied to mining and refining processes. These issues drive the quest for recycling innovations and alternatives, ensuring tungsten's sustained relevance in industries requiring materials that perform under the most demanding conditions, reinforcing its critical role in advancing technology and industrial capabilities.

An introduction to tungsten

Tungsten demand and end-uses

The global tungsten market is undergoing significant growth, propelled by its increasing use in industrial applications, technological advancements, and its pivotal role in the global transition to renewable energy. Tungsten's outstanding physical properties, such as its high melting point, superb tensile strength, and excellent corrosion resistance, make it an essential material across a broad range of industries while reinforcing its importance in renewable energy technologies.

As renewable energy technologies continue to evolve, tungsten's unique attributes make it indispensable in these high-tech applications. The expansion of its role accentuates the need for sustainable practices and effective recycling to accommodate future demands while mitigating environmental impacts.

This expansion is largely driven by growing demands in the industrial sector, the automotive industry, infrastructure developments, and the increasing use in critical technology areas. China maintains its position as the leading global producer of tungsten, which is utilised extensively across various sectors due to its exceptional material properties.

Tungsten carbide constitutes the largest segment of consumption. These products are primarily utilised in cemented carbides (hard metals) for cutting and drilling tools, mining equipment including blast hole drilling, mineral processing components, and construction tools that require high durability and precision.

Due to its exceptional hardness and toughness, tungsten carbide is frequently used in manufacturing sectors that demand durability and precision. This material is gaining popularity in the mining industry as firms transition from steel to tungsten carbide tools, enhancing tool life, improving cost-effectiveness, and boosting productivity.

Tungsten plays a critical role in the steel and superalloys sectors. Ferro tungsten, a primary intermediate, is vital for improving the properties of high-speed steels, tool steels, and special alloys used in aerospace and defence applications, particularly enhancing wear resistance at high temperatures.

Tungsten is extensively used in fabricated products in the lighting and electronics industries. It is a crucial component in items such as incandescent bulb filaments, compact fluorescent lamps, and various electronic components, including integrated circuits, X-ray tubes, and electron emitters.

The transport and mining/construction sectors are major consumers of tungsten, utilising it extensively across various applications. Other significant industries include aerospace, electronics, chemical applications, and increasingly, renewable energy technologies.

Tungsten is proving to be an essential material in the global shift towards renewable energy, supporting various clean technology applications. In solar energy, materials like tungsten disulfide and specialised tungsten wires are crucial in photovoltaic technology, enhancing light absorption and boosting the efficiency of solar cells. Its high thermal conductivity and durability are also essential for components that must withstand extreme environmental conditions.

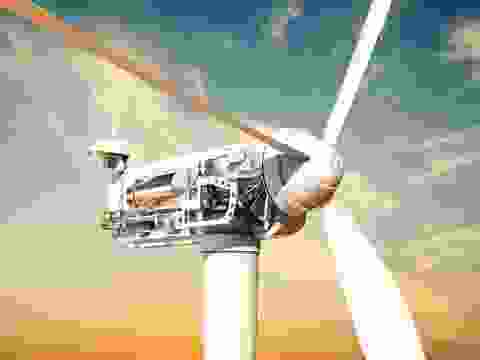

In wind energy, tungsten carbide and heavy alloys are employed in critical components such as bearings, gears, counterweights, and blades. Tungsten's properties help improve the efficiency and extend the operational lifespan of wind turbines, particularly in challenging environments.

Tungsten also enhances the durability and performance of batteries in renewable energy systems, enabling them to withstand higher temperatures and stresses. This is particularly important in electric vehicle batteries, where tungsten supports the high pressures and temperatures experienced during charging and discharging cycles.

The potential of tungsten in fusion energy is also noteworthy. It is used for radiation shielding and plasma-facing components in fusion devices. Its excellent thermal conductivity and resistance to neutron irradiation are crucial for managing the extreme conditions within fusion reactors.

Environmental considerations and the circular economy are becoming increasingly important as the demand for tungsten grows due to its applications in renewable energy. Efforts are underway to develop more environmentally friendly mining and processing methods to minimise ecological impacts. Additionally, recycling tungsten plays a vital role in promoting a circular economy, extending the useful life of products and reducing reliance on primary mining sources.

The shift from tungsten lighting to LED is a notable example of how tungsten usage is decreasing in lighting applications as more energy-efficient alternatives become available. LEDs are particularly advantageous because they consume up to 80% less power than traditional tungsten lights, which directly translates into lower energy consumption. As a result, many manufacturers are either reducing or ceasing the production of less energy-efficient tungsten lamps. This move towards LED lighting represents a substantial opportunity for energy conservation, aligning with global efforts to reduce energy consumption and environmental impact.

Tungsten supply

Tungsten is predominantly sourced from the minerals wolframite and scheelite, which are the principal ores used for extracting this metal. While wolframite accounts for the majority of the global tungsten supply, scheelite covers the remainder. These minerals are mined directly for tungsten and also occur alongside various other metals and minerals in mining operations. Common associations include tin, where tungsten is often recovered as a by-product, as well as copper, gold, molybdenum, bismuth, silver, lead, and zinc. However, the economic viability of these associations can vary significantly depending on the specific mining operation and market conditions. These co-occurrences typically arise in polymetallic deposits, skarn deposits, and quartz veins, where geological conditions favour the coexistence of diverse minerals.

The process of extracting tungsten can involve complex beneficiation due to the properties of the ores and the presence of other minerals, making it economically viable to extract tungsten as a secondary product in some, but not all, cases. This depends largely on the concentration of tungsten in the primary ore and the market prices of both tungsten and the primary metal being mined.

China remains the dominant global producer of tungsten, significantly influencing the market and providing a large portion of the world's supply. However, other countries across various continents are also important players, with some increasing their production capacities or reopening old mines as part of efforts to diversify supply sources and enhance supply chain resilience. Historically, the United Kingdom and Zimbabwe were notable producers, though their current contributions have diminished.

The broad geographical distribution of tungsten mining highlights its global importance and helps stabilize the supply chain despite potential geopolitical or economic challenges. Additionally, environmental considerations associated with tungsten mining have prompted the industry to adopt more sustainable and less impactful mining practices.

Historic tungsten mine producers

Tungsten substitution

Potential substitutes for cemented tungsten carbides encompass various materials, including cemented carbides based on molybdenum carbide, niobium carbide, or titanium carbide, ceramics, ceramic-metallic composites (cermets), and tool steels. While most of these options aim to reduce the tungsten content rather than fully replace it, they offer alternative solutions in certain applications. For instance, molybdenum can substitute for specific tungsten mill products, while molybdenum steels can replace tungsten steels, although tungsten remains prevalent in most cases.

In lighting applications, carbon nanotube filaments, induction technology, and light-emitting diodes (LEDs) offer alternatives to tungsten-based electrodes or filaments. Moreover, depleted uranium or lead can be used in place of tungsten or tungsten alloys in applications requiring high density or radiation shielding capabilities.

Similarly, depleted uranium alloys or hardened steel can substitute for cemented tungsten carbides or tungsten alloys in armor-piercing projectiles. Additionally, vanadium, chrome, cobalt, nickel, copper, graphite, and aluminum alloys broaden the options available for industries seeking alternatives to tungsten-based materials, providing solutions tailored to specific performance requirements and cost considerations.

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.