Titanium

Critical Minerals and The Energy Transition

Navigating the Titanium Market

The titanium market is a dynamic and growing segment of the global materials industry, driven by the metal's exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Primarily used in aerospace applications, titanium is crucial for manufacturing aircraft and spacecraft components, where its lightweight and strong properties significantly enhance performance and fuel efficiency. Beyond aerospace, titanium finds widespread use in the medical field for implants and surgical instruments, capitalizing on its compatibility with the human body. The metal is also increasingly utilized in the automotive, chemical processing, and marine industries for everything from sports cars to desalination plants, highlighting its versatility. Despite its impressive attributes, the titanium market faces high production costs and complex extraction processes, affecting supply and pricing. However, advancements in production technology and recycling are helping to mitigate these issues, making titanium more accessible for various applications. The growing emphasis on lightweight materials for energy efficiency and the metal's unmatched durability and resistance to environmental factors position titanium as a choice for future developments in many cutting-edge industries. As demand across these sectors continues to rise, the titanium market will expand, reflecting its pivotal role in driving innovation and sustainability in global manufacturing and technology advancements.

An introduction to titanium

Titanium demand and end-uses

The titanium market has grown strongly in recent years, driven by the metal’s exceptional properties. Lightweight yet remarkably strong, titanium offers a high strength-to-weight ratio and outstanding corrosion resistance, making it indispensable across a range of traditional and emerging sectors. Its versatility continues to support rising global demand.

Several converging trends are fuelling this momentum, with the most significant demand stemming from aerospace, automotive, medical, and energy applications.

Aerospace remains the leading consumer of titanium, driven by the need for materials that balance strength, low weight, and heat resistance. Titanium contributes directly to fuel efficiency and performance in both commercial and military aircraft. It is used extensively in airframes, such as fuselage sections, wings, and empennage components—as well as in engines, landing gear, and space vehicles. Programmes like the Boeing 787 Dreamliner and Airbus A350 rely heavily on titanium due to its ability to maintain structural integrity under extreme conditions.

Titanium is gaining traction in the automotive industry, particularly in high-performance and electric vehicles (EVs). It is employed in structural components, engine parts, exhaust systems, and battery casings. Its ability to reduce weight while enhancing durability aligns with global efforts to improve energy efficiency and lower emissions. Luxury and motorsport vehicles especially benefit from titanium’s contribution to performance and longevity.

Since the 1950s, titanium has held a critical role in medical applications, prized for its biocompatibility and non-reactive nature. It is widely used in dental implants, joint replacements, cardiovascular stents, and hearing aids. Its non-ferromagnetic properties make it suitable for MRI environments, and its ability to bond naturally with bone enhances long-term implant stability. The sector continues to grow, underpinned by ageing populations and increased medical interventions.

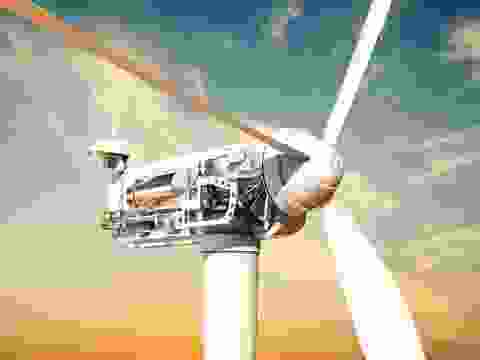

Titanium is increasingly important in the energy sector, particularly amid the global transition to renewable energy. It is used in hydrogen fuel cells, solar panel systems, and condensers for thermal and nuclear power plants. Its corrosion resistance, strength, and thermal stability make it well-suited to the demands of modern energy infrastructure.

Urbanisation and infrastructure development are boosting demand for titanium in construction. Its corrosion resistance and low maintenance requirements make it ideal for long-lasting structures such as bridges, tunnels, and high-speed rail systems. In harsh environments, titanium offers a durable alternative to traditional materials, reducing lifecycle costs and increasing reliability.

Titanium’s resistance to seawater corrosion makes it invaluable in marine applications. It is used in desalination plants, offshore platforms, ship components, and sonar systems. These applications benefit from titanium’s longevity and low maintenance needs, particularly in saltwater and high-pressure environments.

Titanium’s corrosion resistance is especially prized in the chemical industry. It is used in process vessels, heat exchangers, storage tanks, and downhole tools in oil and gas operations. It also features in the pulp and paper sector, where it withstands aggressive bleaching and processing environments, helping to improve operational efficiency.

Beyond heavy industry, titanium has made inroads into consumer markets. It is found in high-end sports equipment, Such as bicycles, golf clubs, and tennis racquets—where lightness and strength are valued. It is also used in premium watches, jewellery, and architectural finishes, offering both aesthetic appeal and functional durability.

Titanium dioxide remains a crucial application, albeit separate from structural uses. It is a key pigment in paints, plastics, paper, and sunscreens, known for its opacity, brightness, and UV-blocking capabilities. Though chemically distinct from structural titanium applications, it represents a major volume driver in the market.

The titanium market is poised for continued growth, bolstered by technological advances and sustainability trends. Additive manufacturing (3D printing) is enabling the production of complex titanium parts with minimal waste, unlocking new efficiencies in the aerospace, medical, and automotive sectors. Meanwhile, the development of recyclable titanium alloys and greener processing techniques reflects rising environmental priorities.

Emerging surface treatments, such as plasma electrolytic oxidation and micro-arc oxidation, are enhancing titanium’s performance in advanced applications. In medical fields, AI-driven personalisation is opening new opportunities for custom titanium implants tailored to individual patients, marking a new frontier in healthcare innovation.

Titanium supply

Titanium supply begins with the extraction of titanium-bearing minerals, primarily ilmenite (FeTiO₃), rutile (TiO₂), and leucoxene, a weathered form of ilmenite. These minerals are mined from both hard rock deposits and heavy mineral sands.

Of these, ilmenite is by far the most abundant, though it contains less titanium dioxide than natural rutile. To enhance its suitability for high-grade applications, ilmenite is often upgraded into synthetic rutile, a refined feedstock with higher TiO₂ content. This upgrading involves removing iron and other impurities through processes such as reduction roasting, acid leaching, or thermal treatment.

Countries such as Australia, India, Japan, and the United States maintain industrial capacity to produce synthetic rutile from ilmenite. Japan, while resource-poor, plays a central role in titanium sponge and mill product production, relying on imported feedstocks.

Titanium feedstocks are processed into several forms depending on end-use requirements, including synthetic rutile, titanium slag (including chloride slag and upgraded slag) and natural rutile.

These feedstocks feed into two primary value chains:

-

Titanium metal production, via sponge, ingots, and mill products for aerospace, defence, and medical applications.

-

Titanium dioxide pigment production, widely used in paints, plastics, paper, and sunscreens.

Titanium minerals ‒ Ilmenite producers (FeTiO3)

Titanium minerals ‒ Rutile producers (TiO2)

Titanium substitution

Common substitutes for titanium include aluminium and stainless steel in structural applications, though they often sacrifice strength-to-weight ratio or corrosion resistance. Composites like carbon fibre are sometimes used in aerospace, while zinc oxide and calcium carbonate may replace titanium dioxide in pigments. However, titanium’s unique properties, such as high strength, low density, and exceptional corrosion resistance, limit the scope of effective substitution. Defence, medical, and high-performance industrial uses have few viable alternatives.

Substitution is more feasible in non-critical applications or where performance trade-offs are acceptable. Nonetheless, advances in material science and recycling may reduce dependence on primary titanium, especially in cost-sensitive sectors. While partial substitution of titanium is possible, titanium remains irreplaceable in many strategic and high-performance domains, reinforcing the importance of stable supply chains for this critical mineral.

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.