Niobium

Critical Minerals and The Energy Transition

Navigating the Niobium Market

Niobium, a critical transition metal, is essential in industry and technology due to its strength, superconductivity, and corrosion resistance. Primarily used in high-strength, low-alloy (HSLA) steel, it enhances toughness, durability, and weldability for automotive, construction, and pipelines. In aerospace, niobium improves turbine blades and jet engine efficiency. It also plays a vital role in superconducting magnets for MRI scanners and particle accelerators. An emerging frontier for niobium is next-generation battery technologies, where its potential to enhance fast-charging and safety features makes it a key material for future energy storage. The market is dominated by Brazil and Canada, with secondary sources from recycling and rare earth by-products. SFA (Oxford) offers expert insights to support strategic decision-making.

An introduction to niobium

Niobium demand and end-uses

Niobium is predominantly used in HSLA steels, enhancing strength, toughness, and weldability, making it indispensable for the automotive industry, structural engineering, and energy pipeline construction. By refining grain structure and preventing corrosion, niobium ensures long-lasting and high-performance steel products.

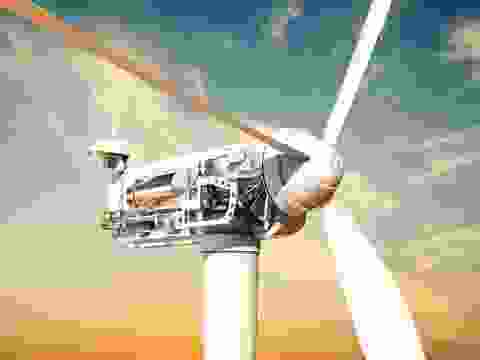

In aerospace applications, niobium alloys are employed in jet engines, gas turbines, and rocket components due to their ability to withstand extreme temperatures and resist oxidation. These properties also make niobium vital in nuclear reactors, where structural integrity at high radiation levels is critical.

Niobium’s superconducting capabilities are leveraged in MRI machines, fusion reactors, and advanced physics research facilities. Superconducting niobium-titanium and niobium-tin alloys are key materials in high-performance electromagnets, supporting cutting-edge technological advancements.

Additionally, niobium finds applications in electronics, where it contributes to energy storage solutions such as lithium-ion batteries and capacitors. Niobium oxides serve as catalysts in chemical processes, including hydrocracking and polymer manufacturing, improving efficiency and sustainability.

Its use in optical coatings and lenses enhances precision instruments, and ongoing research into niobium-based materials is opening new frontiers in quantum computing and next-generation electronics.

Niobium supply

Niobium is primarily sourced from pyrochlore and columbite-bearing ores, with the majority of global production concentrated in Brazil, which holds the largest known reserves. Canada follows as a secondary producer, contributing to global supply stability. Other occurrences are found in countries such as Nigeria, Democratic Republic of Congo, and Russia, though these sources remain limited in production scale.

Niobium is typically mined as a primary product from pyrochlore deposits, while columbite is extracted as a by-product of tin and tantalum mining. The efficiency of niobium production depends on ore concentration, processing technology, and market demand for associated elements.

As niobium plays a strategic role in high-performance alloys, superconductors, and emerging technologies, its supply chain remains a focus for global industries. Recycling efforts and technological innovations in extraction methods are being explored to ensure long-term sustainability and market resilience. SFA (Oxford) offers expert guidance in navigating niobium supply dynamics, assisting clients in making informed decisions within this critical market.

Historic niobium producers

Niobium substitution

Niobium substitution is essential in steel, superalloys, superconductors, ceramics, and energy technologies. In steel and superalloys, it refines the grain structure and forms carbide or nitride precipitates, enhancing strength, toughness, and corrosion resistance. It is widely used in stainless steel for pipelines, automotive parts, and construction materials. In nickel-based superalloys, niobium improves high-temperature strength and oxidation resistance, making it crucial for aerospace turbine blades and jet engines. While vanadium is also used in alloys, niobium offers superior creep resistance, ensuring durability in extreme environments and making it vital for high-performance industries.

In superconductors, niobium plays a key role in optimising electronic properties. In high-temperature superconductors such as 𝑌 𝐵𝑎2𝐶𝑢3𝑂7−𝛿YBa2Cu3O7−δ, replacing copper with niobium modifies electronic interactions, enhancing superconducting behaviour. Niobium-based alloys (𝑁𝑏−𝑇𝑖,𝑁𝑏3𝑆𝑛Nb−Ti,Nb3Sn) are essential in MRI machines, particle accelerators, and fusion reactors due to their ability to maintain superconductivity under strong magnetic fields.

In high-performance ceramics, niobium substitution enhances electrical properties and stability. In perovskite oxides like 𝑆𝑟𝑇𝑖3SrTiO3, replacing titanium with niobium introduces free electrons, significantly boosting conductivity for electronic components and sensors. In dielectric and ferroelectric materials such as 𝐵𝑎𝑇𝑖𝑂3BaTiO3, niobium improves dielectric and piezoelectric properties, making these materials more suitable for capacitors, transducers, and actuators. Compared to vanadium, niobium offers better thermal and chemical stability, making it the preferred choice for high-performance ceramics.

Finally, in energy storage and fuel cells, niobium enhances battery performance and catalytic efficiency. It improves lithium-ion diffusion in batteries, leading to faster charging and longer cycle life. In solid oxide fuel cells (SOFCs), niobium increases ionic conductivity and efficiency, supporting cleaner energy conversion. While similar to vanadium, niobium offers superior durability but is rarer and more expensive, requiring careful material optimisation.

Niobium market reports

SFA’s niobium reports offer a unique value chain perspective on both the ferroniobium and high-purity niobium markets. Designed to meet short-, medium-, and long-term stakeholder needs, our comprehensive reports provide essential insights to help navigate the future of this critical material.

Niobium Market and Price Outlook to 2030

This cutting-edge report explores key trends, market influences, and emerging niobium technologies shaping the industry through 2030.

Niobium Market and Price Outlook to 2035

This ground-breaking, forward-looking report analyses the trends and influences on the niobium market and emerging technologies out to 2035.

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.