Molybdenum

Critical Minerals and The Energy Transition

Navigating the Molybdenum Market

Molybdenum, renowned for its heat and corrosion resistance, is crucial in the steel, aerospace, and electronics industries. Its ability to withstand extreme temperatures makes it essential for high-strength steel and superalloys used in jet engines, electrical contacts, and industrial machinery. In the chemical industry, it catalyses the refinement of petroleum and the production of high-performance lubricants. Molybdenum's role is expanding in renewable energy, particularly in solar photovoltaic cells and wind turbines, where it enhances efficiency and durability. As energy technologies evolve, molybdenum's importance in these applications underscores its contribution to sustainable energy solutions. However, the molybdenum market contends with price volatility due to fluctuating mining outputs and the cyclical nature of the steel industry. Supply challenges, including geopolitical tensions and stringent environmental regulations, affect production. Recycling efforts are increasing, emphasising molybdenum's role in sustainability. Molybdenum remains vital for global development and technological advancement, with ongoing initiatives to enhance its sustainable use and explore substitutes in certain applications, balancing dependency with innovation.

An introduction to molybdenum

Molybdenum demand and end-uses

Molybdenum, with its silvery-white sheen and remarkable properties such as strength, heat resistance, and corrosion resilience, occupies a crucial role in both established industrial applications and the burgeoning energy transition. While its vital contributions to various technologies often go unnoticed, molybdenum remains an unsung hero in industrial progress and the shift towards green energy.

This element is indispensable across many sectors, playing a central role in both traditional industries and the clean energy revolution. As the pace of the energy transition quickens, the importance of molybdenum is set to increase, particularly in areas such as wind, solar, energy storage, and hydrogen technologies. Despite facing supply challenges, the future of molybdenum promises continued innovation, highlighting its essential role in a sustainable global energy system.

Molybdenum's primary applications are in steel production, engineering alloys, superalloys, and chemical processes. In the steel industry, it significantly enhances the strength, hardness, electrical conductivity, and resistance to wear and corrosion. Alloys containing molybdenum are widely used in critical engine components and structural applications that demand durability under extreme conditions. Beyond the steel industry, molybdenum has a broad range of uses across various industrial sectors. It enhances the performance of heating elements, drills, and saw blades, serves as a lubricant additive in industrial processes, acts as a catalyst in refining operations, and is used in circuit board inks, pigments, and electrodes for specific functional properties. The aerospace industry leverages molybdenum's heat resistance and strength, and its biocompatibility has made it valuable in the manufacturing of medical implants and devices.

In solar photovoltaic (PV) cells, particularly those of the thin-film variety, molybdenum plays a critical role as a back contact and back electrode layer. It enhances conductivity and operational efficiency, which are crucial for maximizing solar energy capture and minimizing costs. Molybdenum's robust properties enable it to withstand process temperatures up to 650°C, resist high-temperature corrosion by selenium, facilitate sodium diffusion from soda lime glass substrates into the absorber during processing (thereby enhancing conversion efficiency by about 2%), and form beneficial selenium compounds at the molybdenum/Copper Indium Gallium Selenide (CIGS) interface. Technologies such as CIGS and Cadmium Telluride (CdTe) solar cells, which incorporate molybdenum, are noted for having some of the shortest energy payback periods among all PV technologies.

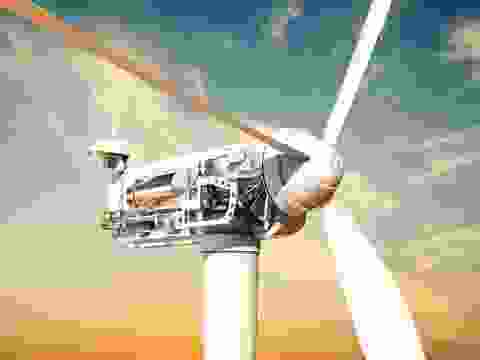

Molybdenum alloys are also preferred for turbine components such as gears, shafts, and bearings in wind energy, due to their strength and corrosion resistance. As renewable energy infrastructures expand, effective energy storage becomes crucial. Molybdenum is instrumental in developing advanced energy storage devices like supercapacitors and batteries, which are particularly promising for hybrid transportation systems. Additionally, molybdenum is essential in the burgeoning hydrogen economy, critical for green technologies and the advanced alloys required for hydrogen production systems.

Molybdenum supply

China is the world's largest producer and consumer of molybdenum, followed by Chile as the second-largest producer. Additional key producers include the United States, Peru, Mexico, Armenia, Mongolia, Iran, Canada, Russia, Poland, Brazil, the Kyrgyz Republic, and Norway.

Molybdenum is primarily extracted as a byproduct of copper mining, though some operations focus on molybdenum as their primary product. The extraction process typically involves extensive drilling, blasting, and hauling. The most commonly found mineral of molybdenum is molybdenite (MoS2), which is the principal source in mining operations. Other less common minerals include powellite (calcium molybdate) and wulfenite (lead molybdate).

The primary challenges in the molybdenum supply chain arise from mining difficulties and geopolitical issues. In China, stringent environmental regulations and the demand for more efficient mining practices have slowed production. In Chile, issues such as operational disruptions and water scarcity have likewise impacted output. These problems contribute to supply constraints, subsequently putting upward pressure on molybdenum prices.

Recycling initiatives are increasingly significant, focusing on the recovery of molybdenum from end-of-life products and manufacturing waste. These efforts enhance the sustainability profile of technologies that depend on molybdenum.

Historic molybdenum producers

Molybdenum substitution

Molybdenum is essential in several industrial processes, but alternatives are being explored to ensure sustainability and reduce dependency across key sectors.

In steel and alloys, tungsten and vanadium stand out as the most common substitutes for molybdenum in high-speed steels. These elements are valued for their ability to maintain similar levels of hardness and high-temperature strength. However, it's important to note that they might alter other material properties, such as toughness or corrosion resistance. Additionally, niobium serves as an alternative in stainless steel and other speciality alloys, particularly valued for its heat resistance.

The catalyst industry, especially in petroleum refining, also sees substitution. Molybdenum is traditionally used to remove sulfur from crude oil, but cobalt and nickel can serve as viable alternatives. They influence the efficiency and selectivity of the catalytic process and often require adjustments to operations.

In lubricants, molybdenum disulfide is a preferred choice due to its exceptional ability to withstand high pressures and temperatures. Alternatives like graphite and tungsten disulfide are considered, offering similar properties but with different effectiveness levels depending on the application environment.

The electronics sector also explores substitutes, particularly in the production of thin films and other semiconductor devices. Materials such as tantalum and titanium are sometimes used instead of molybdenum, especially in components like capacitors and resistors. These materials can offer different electrical characteristics, which may be advantageous depending on the specifications of the device.

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.