Boron

Critical Minerals and The Energy Transition

Navigating the Boron Market

Boron is a quietly indispensable element, underpinning a diverse range of industrial, technological, and agricultural applications. Its versatility stems from unique chemical and physical properties that make it critical in sectors as varied as glass and ceramics manufacturing, semiconductors, agriculture, nuclear energy, metallurgy, and clean energy technologies. As the global economy shifts towards decarbonisation and resource efficiency, boron’s strategic value is increasingly recognised, not only for its role in traditional industries but also for its growing relevance to the energy transition. From solar panels and high-performance magnets to advanced alloys and next-generation batteries, boron plays a pivotal role in enabling sustainable technologies. Despite its broad industrial footprint, boron supply is geographically concentrated, with production dominated by a handful of countries. This market concentration, coupled with rising demand across key sectors, positions boron as a critical mineral of strategic importance. SFA (Oxford) explores the evolving dynamics of the boron market, mapping its supply chain, end-use applications, and emerging trends to provide a comprehensive understanding of where this essential element fits within the future of global industry and clean energy innovation.

An introduction to boron

Boron demand and end-uses

Boron is a versatile element used in various industries, and its demand has been steadily increasing due to its wide range of applications. Boron demand is predominantly fueled by critical sectors such as agriculture, glass and ceramics, electronics, energy, cleaning and alloying.

Boron is an essential micronutrient for plant growth in agriculture and is widely utilised in fertilisers to improve crop yields and quality. Boron is involved in cell wall formation, pollen germination, fruit development, flowering and seed formation, influencing the uptake and transport of other nutrients within plants to enhance high-quality crops. Boron deficiency can result in various crop disorders, including hollow heart in potatoes, brown heart in lettuce, and internal browning in fruits like apples and pears.

Boron is a critical ingredient in borosilicate glass, which is resistant to thermal shock (temperature stability and durability), such as laboratory glassware and cookware. In fibreglass, boron compounds help to increase the strength and flexibility of the glass fibres, making them ideal for use in insulation materials, automotive parts, and construction. Boron is also used in ceramics to improve toughness and durability.

Boron is crucial in the semiconductor industry, specifically in silicon wafer doping, to enhance electrical conductivity. This process creates p-type semiconductors, which are vital for electronic devices like smartphones, computers, and renewable energy systems. By introducing "holes" or positive charge carriers, boron doping allows for controlled electricity movement in semiconductors, ensuring device performance and reliability. This is critical for the functioning of various electronic devices, including transistors, diodes, and integrated circuits, which form the foundation of modern electronics, from smartphones and computers to advanced medical equipment and renewable energy systems.

In nuclear reactors, boron is used as a neutron absorber. This means it helps control the nuclear fission process, which splits atomic nuclei to release energy. By absorbing excess neutrons, boron prevents the nuclear reaction from escalating uncontrollably, thus playing a critical safety role. It's often added to reactors' cooling water, which can be easily adjusted to maintain the desired fission rate, ensuring the reactor operates safely and efficiently.

Boron is used in producing solar panels, specifically in creating silicon wafers, a key component of most solar cells. Boron is doped into silicon to form p-type silicon with positive charge carriers. When combined with n-type silicon, which has negative charge carriers, it creates a p-n junction, the fundamental building block of a solar cell. This junction allows solar panels to convert sunlight into electricity efficiently. By facilitating this conversion, boron produces clean, renewable energy from solar panels.

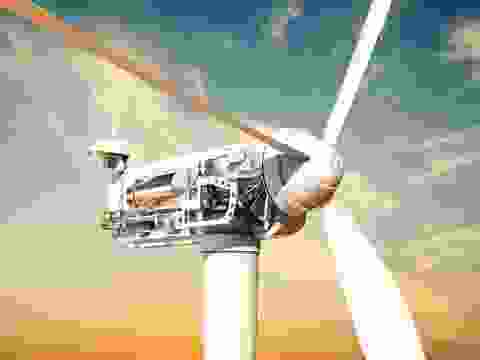

In metallurgy, boron is added to steel and aluminium to increase hardness and resistance to corrosion. It is used in the automotive industry for its high strength and lightweight properties, contributing to vehicle safety and fuel efficiency. Parts like seat belts, airbags, and bumpers are often made from boron steel due to its exceptional strength and ability to absorb impact. In construction, high-strength boron steel is used to manufacture tools and machinery, such as bulldozer blades, excavator buckets, and hand tools. These tools benefit from boron steel's resistance to wear and deformation. In wind turbines, boron steel can be used to construct gears and other components that require high strength and resistance to harsh environmental conditions.

Boron-aluminium alloys are used in aerospace for components that require lightweight materials with high strength and corrosion resistance. These include aircraft frames, skin, and parts of the propulsion system. Further uses are in consumer products such as sports equipment, where boron is added to aluminium to manufacture high-performance sports equipment, such as bicycles and baseball bats, offering an excellent balance of weight, strength, and durability. Boron-aluminium alloys are used in the casings of laptops, smartphones, and other portable devices for their lightweight and durable properties, contributing to their sleekness and resistance to daily wear and tear.

Additionally, its applications in detergents and bleaches enhance cleaning efficiency, and it is incorporated into metals like steel and aluminium to boost hardness and corrosion resistance, indicating its broad utility. These diverse applications highlight boron's significance across various industrial processes and its potential for future demand growth driven by technological advancements and the global shift towards renewable energy.

Boron demand is expected to grow, mainly driven by the renewable energy sector, advancements in agriculture, and the continuous demand in glass and ceramics manufacturing. The increasing interest in electric vehicles (EVs) and energy storage solutions also presents potential growth opportunities for boron, especially in battery technologies where borates are being investigated for use in high-capacity lithium-ion batteries.

Boron supply

The global supply of boron primarily comes from borate minerals, with the largest reserves found in a few key regions around the world. Turkey, the United States, and Russia are among the leading producers of boron, collectively accounting for a significant portion of global production. Most of the world's boron reserves are located in a few countries, including Turkey, the United States, and Russia, making the market sensitive to changes in export policies and international relations.

Turkey holds the largest known reserves of boron minerals, particularly in the Bigadiç district in the province of Balıkesir. The country is a major exporter of boron products, with the state-owned Eti Maden being the leading producer.

The United States is another significant producer of boron, primarily from deposits located in California, particularly the Mojave Desert region. The Borax mine in Boron, California, operated by Rio Tinto, is one of the largest boron mines globally.

Russia also has substantial boron reserves, mainly located in the Ural Mountains region. The country's boron production is primarily from the Solikamsk Magnesium Works (SMW), which extracts boron as a byproduct of magnesium production.

Other countries such as Argentina, Chile, Peru, and Serbia also contribute to global boron production, although to a lesser extent compared to the major producers mentioned above.

Boron substitution

Depending on the specific application and desired properties, boron can be substituted with various elements. Some common elements used for substitution in place of boron include silicon, aluminium, phosphorus, arsenic, carbon compounds and other alternative compounds.

Silicon is often substituted for boron in semiconductor materials and certain ceramics. Silicon offers similar chemical properties and can be doped into silicon wafers to achieve specific electronic characteristics.

Aluminum can replace boron in borosilicate glasses and ceramics, altering thermal expansion and mechanical strength properties. Aluminium substitution can modify the material's performance while maintaining its overall composition.

Phosphorus is another dopant commonly used in semiconductor manufacturing, replacing boron to achieve specific electrical properties in silicon-based devices.

Arsenic is utilized as a dopant in semiconductor materials as an alternative to boron, offering different electronic characteristics depending on the application requirements.

Carbon compounds can sometimes be used as substitutes for boron-containing chemicals, especially in organic synthesis and pharmaceutical manufacturing processes.

Additionally, in chemical reactions and industrial processes involving boron-containing compounds, alternative compounds or functional groups may be employed as substitutes to achieve similar outcomes while reducing reliance on boron resources such as titanium dioxide (high-performance ceramics), zirconium dioxide (for high thermal resistance and mechanical strength), phosphates (calcium phosphate, aluminium phosphate), aluminosilicate (adsorbents, catalysts, and ceramics), and magnesium compounds (flame retardants or refractories).

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.