Vanadium

Critical Minerals and The Energy Transition

Navigating the Vanadium Market

The vanadium market is entering a pivotal decade, shaped by the convergence of global infrastructure demands, clean energy priorities, and strategic resource planning. Historically dominated by its role in strengthening steel, vanadium is now gaining traction in high-growth sectors such as grid-scale energy storage and advanced manufacturing. As nations seek to decarbonise and enhance energy resilience, vanadium’s unique properties, particularly its strength-enhancing, corrosion-resistant, and electrochemical characteristics—are positioning it as a critical mineral for both industrial development and the energy transition. However, the vanadium market remains complex and relatively opaque, influenced by co- and by-product sourcing, supply concentration, geopolitical constraints, and limited substitutability. As demand rises across diverse end-uses, from construction and aerospace to vanadium redox flow batteries (VRFBs), stakeholders must navigate evolving price dynamics, shifting supply chains, and emerging policy frameworks. This section offers a comprehensive overview of vanadium’s role in the global economy, its demand fundamentals, supply mechanisms, and the structural forces reshaping its future market trajectory.

An introduction to vanadium

Vanadium demand and end-uses

The global vanadium market is undergoing a structural transformation, driven by shifting demand across both traditional and emerging sectors. This evolution is underpinned by vanadium’s critical role in steel strengthening, renewable energy storage, and a range of high-performance industrial applications. As countries intensify efforts to decarbonise and modernise infrastructure, vanadium’s unique metallurgical and electrochemical properties position it as a strategic mineral. This report synthesises current data and projections to examine vanadium demand drivers, key applications, supply chain vulnerabilities, and long-term market prospects.

The steel sector remains the primary consumer of vanadium, accounting for approximately 85% of global demand. Vanadium is mainly used to enhance the strength, durability, and corrosion resistance of high-strength low-alloy (HSLA) steels, particularly in construction rebar. In September 2024, China revised its national rebar standards to mandate higher vanadium content, aligning with its broader goal to improve infrastructure resilience. China’s construction sector alone accounts for more than 60% of global vanadium use.

Although China’s construction market has slowed, vanadium demand remains resilient. Emerging economies are increasingly adopting vanadium-intensive practices. India, for example, has significantly increased crude steel production, generating secondary demand for vanadium alloys. Vanadium’s ability to reduce steel weight without compromising structural integrity is essential for infrastructure such as bridges, pipelines, and buildings in earthquake-prone regions like California.

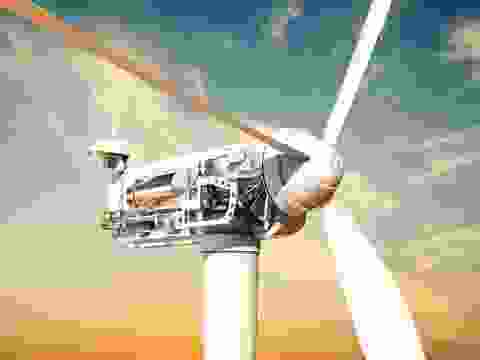

Vanadium redox flow batteries (VRFBs) represent the most disruptive growth frontier for vanadium demand. Unlike lithium-ion batteries, VRFBs utilise vanadium electrolytes in liquid form, offering scalable capacity (from 4 to 250 MWh), exceptional cycle life exceeding 10,000 cycles, and inherent safety advantages. China leads this surge, deploying VRFBs to stabilise renewable-heavy power grids and potentially surpassing steel-related vanadium use by mid-century. California exemplifies this shift, integrating VRFBs to support renewable energy and grid resilience. Projects by Sumitomo Electric in Japan have demonstrated storage durations of 5–10 hours with round-trip efficiencies of 65–75%.

Vanadium plays a critical role across multiple metallurgical sectors. In construction, vanadium-micro-alloyed rebar enables a 20–30% reduction in material usage while still meeting stringent seismic and durability standards. China’s updated GB/T 1499.2-2024 standard mandates the use of vanadium nitride additives, increasing vanadium content to 0.03–0.05% per tonne of rebar. In aerospace, vanadium is vital in titanium alloys such as Ti-6Al-4V, widely used in jet engine components for their high strength-to-weight ratio. Meanwhile, the automotive industry employs advanced high-strength steels (AHSS) containing 0.05–0.1% vanadium to produce lighter, more fuel-efficient vehicle frames without compromising safety.

Vanadium also serves several critical non-metallurgical functions, with VRFBs again standing out as the most prominent application. A typical 1 MW/10 MWh VRFB system requires 7–10 tonnes of vanadium pentoxide (V₂O₅), with the electrolyte alone accounting for 30–40% of total system costs. Large-scale installations, such as Sumitomo’s 15 MW/60 MWh project in Hokkaido, have demonstrated the ability to reduce wind energy curtailment by 18%, underscoring VRFBs’ role in renewable energy firming. Vanadium-based catalysts are equally important in industry, enabling sulphuric acid production via the Contact Process and facilitating petroleum desulphurisation for over 200 million tonnes of sulphur annually. In addition, vanadium oxide (V₂O₅) provides yellow-blue colouration in glass and ceramics, while vanadium nitride enhances wear resistance in cutting tools, making it vital for high-performance coatings in precision manufacturing. Its inherent hardness, thermal stability, and resistance to wear also make vanadium alloys exceptionally well-suited for industrial tooling and die applications, where materials must endure repeated mechanical stress, abrasive environments, and thermal cycling without degradation.

Vanadium supply

Vanadium is primarily obtained through the extraction and processing of vanadium-bearing materials, but it is rarely mined as a standalone commodity. Instead, it is most commonly recovered as a by-product or co-product of other mining and industrial operations. The principal source is vanadium-bearing titanomagnetite ores, which are typically processed during ironmaking in blast furnaces or electric arc furnaces. In these operations, vanadium partitions into the slag rather than the pig iron and is later extracted from the vanadium-rich slag through roasting, leaching, and purification to produce vanadium pentoxide (V₂O₅).

In addition to titanomagnetite sources, vanadium is also recovered as a co-product from uranium mining, particularly from sandstone-hosted uranium-vanadium deposits in regions such as the western United States. Here, vanadium minerals like carnotite and roscoelite are extracted alongside uranium during acid or alkaline leaching.

Another potential source is bauxite residue (red mud), a by-product of alumina production. In some cases, vanadium is present in economically recoverable quantities, though commercial extraction remains limited due to processing complexity.

A growing share of vanadium supply also comes from oil refining by-products, particularly fly ash and residues from the combustion of heavy oils, which can contain up to 5–15% vanadium pentoxide. These are processed via hydrometallurgical methods to recover vanadium, especially in countries without primary vanadium mining. While technically classified as secondary sources, these oil-derived materials are essential to global vanadium supply—particularly in regions such as North America and Japan.

Finally, recycling from spent catalysts (used in petroleum refining and sulphuric acid production) and steel slag also contributes significantly to vanadium supply. These secondary sources are becoming increasingly important as producers seek to reduce reliance on virgin ore, diversify supply chains, and mitigate environmental impacts.

Vanadium mine producers

Note: This includes vanadium found in slag products, and excludes vanadium sourced as a by-product from the refining and combustion of heavy oils.

Historic vanadium mine producers

Vanadium substitution

Vanadium is difficult to substitute in many of its key applications due to its unique combination of strength, corrosion resistance, and electrochemical stability. In steelmaking, alternatives such as niobium or titanium can partially replace vanadium in high-strength low-alloy (HSLA) steels, but these substitutes often require higher doses or offer less flexibility in performance, raising both material and processing costs. In aerospace, vanadium-titanium alloys like Ti-6Al-4V have no direct equivalent with the same strength-to-weight ratio and thermal stability.

In energy storage, vanadium redox flow batteries (VRFBs) have few viable substitutes for long-duration applications. Alternatives like iron-flow or zinc-bromine batteries exist but face limitations in efficiency, lifespan, or safety. For catalytic uses, molybdenum or tungsten can sometimes replace vanadium, though typically at higher cost or with reduced effectiveness.

Overall, while substitution is technically possible in some sectors, performance trade-offs, economic inefficiencies, and supply security concerns make vanadium a strategically resilient mineral with limited practical alternatives.

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.