Copper

Critical Minerals and The Energy Transition

Navigating the Copper Market

Copper is key to the global energy transition, underpinning everything from renewable power systems to electric vehicles and advanced grid infrastructure. As countries race to decarbonise and electrify their economies, demand for copper is expected to rise sharply, placing significant pressure on an already strained global supply chain. The metal’s unmatched conductivity, durability, and recyclability make it indispensable in clean energy technologies. Whether enabling the efficient transmission of electricity or powering the motors of electric vehicles, copper’s role is foundational and growing. Yet, while demand surges, supply remains constrained by long permitting timelines, declining ore grades, and mounting geopolitical and environmental challenges. Major producing nations, including Chile, Peru, the DRC, China, and the United States, face rising regulatory scrutiny, while technological innovation and recycling capacity struggle to close the gap.

An introduction to copper

Copper demand and end-uses

Copper lies at the heart of the global energy transition, with demand set to rise sharply as renewable energy deployment, electric vehicle uptake, and grid modernisation accelerate. Thanks to its unique combination of electrical conductivity, durability, and resistance to corrosion, copper remains irreplaceable in many clean energy applications, offering both immense opportunity and mounting challenges as supply struggles to keep pace.

As the world intensifies efforts to achieve net-zero emissions, copper is becoming a cornerstone of the shift towards electrification. Its vital role spans across solar and wind technologies, battery storage systems, electric mobility, and transmission infrastructure. The metal’s recyclability adds to its appeal, offering a sustainable edge that few other materials can match.

Meeting this surging demand will require a step change in mining investment, coupled with innovation in recycling and extraction methods. Governments and industries alike will need to adopt more strategic, long-term planning if copper is to support the energy transition at the necessary scale.

Although copper has been central to power systems for more than two centuries, its role is expanding rapidly within the renewables sector. As the second most conductive metal after silver, it helps reduce energy losses during transmission while offering long-term durability, critical qualities for solar farms and wind turbines exposed to the elements.

The strategic importance of copper is also drawing geopolitical attention. As countries seek to secure their own supplies for domestic energy transitions, copper could become a flashpoint for competition, echoing recent dynamics seen with lithium, cobalt, and other critical minerals.

A looming imbalance between supply and demand presents serious implications. Shortages could drive up the cost of renewable energy technologies and electric vehicles, potentially slowing adoption just as global climate targets become more urgent.

Despite the presence of cheaper alternatives, copper’s combination of conductivity, flexibility, and recyclability makes it difficult to replace. Unlike many materials, it can be recycled indefinitely without losing performance, an increasingly vital quality as concerns mount over the environmental impacts of raw material extraction. Without copper’s efficiency, components such as motors, transformers, and cables would require significantly more material to deliver the same output.

Renewable energy systems are far more copper-intensive than conventional fossil fuel power. This is largely due to their distributed nature: connecting decentralised generation units to storage and the grid demands extensive cabling across wide areas. As a result, renewable-based systems typically require between six and twelve times more copper than their fossil-fuel counterparts.

Copper demand is rising at a rapid pace. Electricity networks will need far greater quantities of copper to handle renewables' intermittency and maintain grid reliability. Grid-scale battery storage, in particular, is expected to see the most dramatic growth in copper usage over the coming decades.

Among clean technologies, solar photovoltaic systems stand out for their copper intensity. A typical solar installation uses considerably more copper per unit of capacity than fossil fuel plants, with some estimates placing the difference as high as forty-fold. In a solar installation, copper is utilised throughout the system in multiple components:

-

Interconnection wires between photovoltaic modules

-

Earthing grids in electrode earth pegs, horizontal plates, and cables

-

DC cables connecting photovoltaic modules to inverters

-

Low-voltage AC cables linking inverters to metering systems

-

High-voltage AC cables for grid connection

-

Communication cables

-

Inverters and power electronics

-

Transformer windings

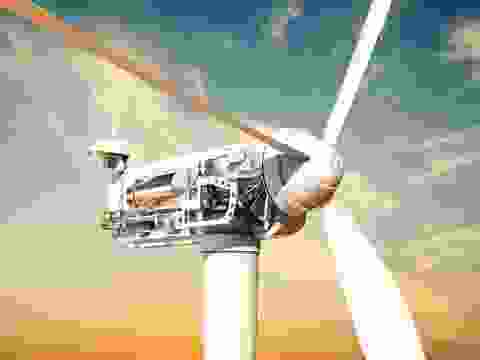

Wind farms are another copper-intensive renewable technology. A single wind farm can require between 2,000 and 7,000 tonnes of copper, while an individual 660-kilowatt wind turbine contains around 350 kg of the metal.

China leads global copper consumption for wind energy, and with strong investment in both wind and solar, the Asia-Pacific region is poised to drive substantial growth in this sector.

Meanwhile, the electrification of transport is dramatically boosting copper demand. Electric vehicles (EVs) require at least two to three times more copper than conventional internal combustion engine vehicles, owing to copper-rich components such as electric motors, inverters, and wiring. Electric buses are even more copper-intensive, using at least ten times as much copper as their diesel-powered counterparts.

The ongoing expansion of electricity networks to accommodate renewable energy is also a key driver of copper demand. Copper remains vital for transmitting and distributing electricity generated from renewable sources.

Copper prices play a pivotal role in the economics of clean energy. Higher copper costs can raise the price of renewable energy systems, EVs, and grid infrastructure, potentially hindering project viability. Conversely, lower copper prices improve the affordability and profitability of such projects, helping to accelerate the energy transition.

Copper supply

The copper supply chain faces mounting pressure as global demand rises in tandem with the energy transition. However, the pathway to scaling up supply is complicated by a range of structural, environmental, and geopolitical challenges.

Securing regulatory approval for new copper mines has become increasingly difficult, with approvals falling to their lowest level in 15 years. Developing a new mine typically takes between 10 and 20 years, meaning the industry cannot rapidly respond to demand surges. Meanwhile, declining ore grades in existing operations require more energy and water per tonne of copper extracted, increasing environmental and economic costs.

Many of the world’s top copper producers face additional hurdles. Chile and Peru, the two largest producers, have experienced community opposition, water stress, and permitting delays. In the Democratic Republic of the Congo (DRC), Zambia, and Indonesia, political and regulatory uncertainties have disrupted project timelines. China and the United States remain key producers, but domestic resource limitations may constrain future expansion. Other significant mining countries include Russia, Australia, Mexico, Kazakhstan, Canada, Mongolia, Poland, Brazil, Iran, and Panama.

A broader set of nations, including Turkey, Serbia, Spain, South Africa, Vietnam, Finland, Saudi Arabia, India, Pakistan, Botswana, Morocco, and the Philippines, also contribute to global copper output at various stages of mining, smelting, and refining. Emerging producers such as Uzbekistan, Laos, Ecuador, Tanzania, Namibia, and Georgia are playing an increasingly important role, particularly as investment shifts to new jurisdictions.

Copper smelting and refining capacity is similarly concentrated. In addition to mine producers, countries such as Japan, South Korea, Germany, Belgium, and Italy are major players in copper refining and processing. The integration of mining and downstream infrastructure varies across nations, influencing their strategic leverage in the global copper value chain.

The industry is also grappling with growing scrutiny from regulators and local communities, which has delayed or curtailed operations in several jurisdictions. Long-standing issues around land use, water rights, environmental damage, and social impact are increasingly shaping public and political attitudes toward mining.

Nevertheless, technological advancements offer some hope for easing supply constraints. Innovations such as coarse particle recovery, sulphide leaching, and artificial intelligence-driven process optimisation are helping maximise output from existing operations and lower-grade ores.

Recycling is also a critical component of copper supply. As one of the few materials that can be recycled repeatedly without loss of quality, secondary copper will be vital in bridging the supply gap and reducing dependence on new extraction. Countries with advanced recycling systems will be better positioned to buffer against primary supply volatility.

Current mine producers of copper

Historic copper smelter producers

Refined copper producers

Copper substitution

Copper is challenging to substitute in many of its core applications due to its exceptional combination of electrical and thermal conductivity, corrosion resistance, and workability. In electrical wiring and power infrastructure, aluminium is the most common alternative, but it offers only about 60% of copper’s conductivity by volume, requiring larger cross-sections that increase installation complexity and reduce efficiency. In high-performance electronics, no material matches copper's conductivity and reliability without compromising on miniaturisation or heat dissipation.

For electric motors, especially in EVs and wind turbines, aluminium and superconducting materials have been explored as substitutes, but they tend to reduce power density or increase system complexity and cost. In plumbing and heat exchangers, plastic polymers or stainless steel can replace copper in some cases, but they often lack the antimicrobial properties or thermal efficiency of copper, especially in critical environments.

While sector-specific substitutions are technically feasible, they often involve performance penalties, design adjustments, or higher lifecycle costs. These limitations, combined with growing demand across clean energy and digital infrastructure, make copper a foundational and strategically resilient metal with few practical alternatives at scale.

The Battery Metals market

SFA (Oxford) also provides regular market intelligence on the battery metal markets. Discover some of the critical materials used in batteries.

Meet the Critical Minerals team

Trusted advice from a dedicated team of experts.

Henk de Hoop

Chief Executive Officer

Beresford Clarke

Managing Director: Technical & Research

Jamie Underwood

Principal Consultant

Ismet Soyocak

ESG & Critical Minerals Lead

Rj Coetzee

Senior Market Analyst: Battery Materials and Technologies

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.